Polycarbonate is a type of thermoplastic polymer that has become increasingly popular in various industries due to its unique properties and versatility. In this article, we will delve into the properties of polycarbonate, its production process, price, market trends, and applications.

Properties of Polycarbonate

Polycarbonate is a transparent and colorless thermoplastic polymer that is highly impact-resistant, making it ideal for applications that require durability and strength. It is also lightweight, with a density of approximately 1.2 g/cm³, which makes it a popular choice for applications that require lightweight materials. Additionally, polycarbonate has excellent optical clarity, high heat resistance, and is resistant to UV radiation.

Production of Polycarbonate

Polycarbonate is produced through a chemical process called the “interfacial polymerization process.” This process involves the reaction between bisphenol A (BPA) and phosgene, which results in the formation of polycarbonate. The process requires strict control of temperature, pressure, and reaction time to ensure the production of high-quality polycarbonate.

Price of Polycarbonate

The price of polycarbonate varies depending on several factors, including the purity of the material, the manufacturing process used, and the demand for the material in the market. Generally, the cost of polycarbonate is higher than other thermoplastics due to its unique properties and production process.

Market Trends for Polycarbonate

The market for polycarbonate is growing rapidly due to the increasing demand for lightweight and durable materials in various industries. The automotive industry is one of the largest consumers of polycarbonate, as it is used in the production of lightweight and impact-resistant components. Additionally, polycarbonate is widely used in the electronics industry for the production of electronic components and mobile phone screens. The medical industry is also a significant consumer of polycarbonate, where it is used in the production of medical devices due to its biocompatibility and sterilization capabilities.

Applications of Polycarbonate

Polycarbonate is used in a wide range of applications, including:

- Automotive: Polycarbonate is used in the production of lightweight and impact-resistant components in the automotive industry, including headlights, taillights, and instrument panels.

- Electronics: Polycarbonate is used in the production of electronic components, including mobile phone screens, laptop casings, and television screens.

- Medical: Polycarbonate is used in the production of medical devices due to its biocompatibility and sterilization capabilities. It is used in the production of surgical instruments, implantable devices, and diagnostic equipment.

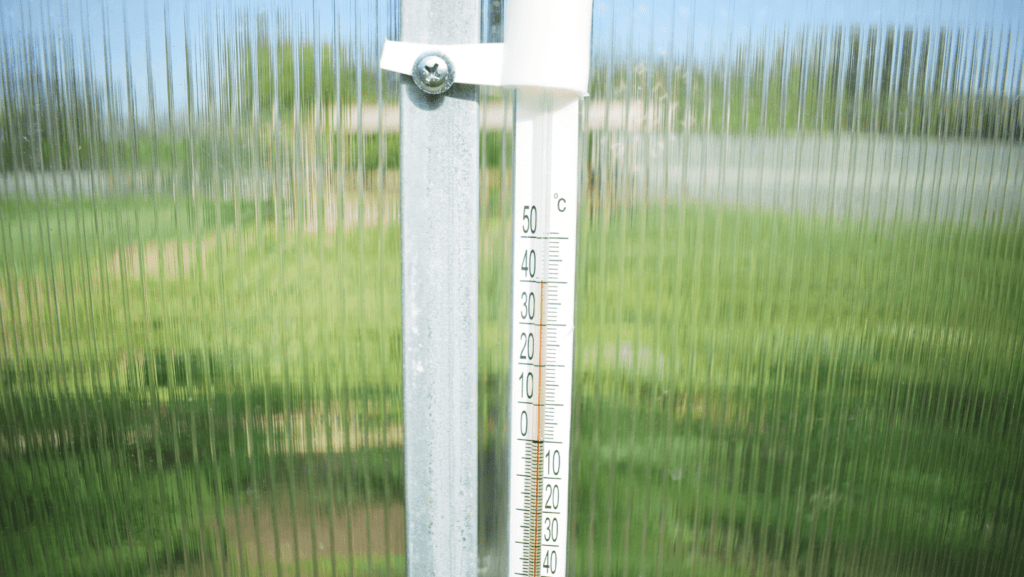

- Construction: Polycarbonate is used in the construction industry for the production of roofing sheets, skylights, and greenhouse panels.

- Packaging: Polycarbonate is used in the production of food and beverage packaging, including reusable water bottles and baby bottles.

In conclusion, polycarbonate is a versatile material with unique properties that make it a popular choice in various industries. Its production process is complex, and the cost of the material is relatively high. However, its benefits, such as lightweight, impact resistance, and optical clarity, make it an excellent choice for many applications. With the market for polycarbonate growing rapidly, it is likely to continue playing an essential role in the manufacturing and engineering industries for years to come.